Design contract service

【Reference】

- We will finish the products prototyped by our company, such as direct bonding, so that they can be exhibited at the exhibition.

- We will propose a method that matches the demo machine you requested, such as creating a housing using 3D printer modeling / creating a housing using sheet metal.

- Boards and FPCs can also be created / procured if the circuit is provided by the customer.

- We can also handle only a part, such as structural design only.

Flow until creation

① Meeting with the customer for specifications (get the following information)

- Schematic image (ponchi-e)

- Storage parts (LCD, board, battery, etc.)

- Drawing or actual item, etc.

- Information on desired quantity / desired delivery date

② We will study the concept, create and submit the concept.

- 3D-CAD (2D-CAD is also possible)

③ Structure determination / specification fix (by customer approval)

④ Manufacture (creation of parts drawings, procurement of parts, assembly), delivery

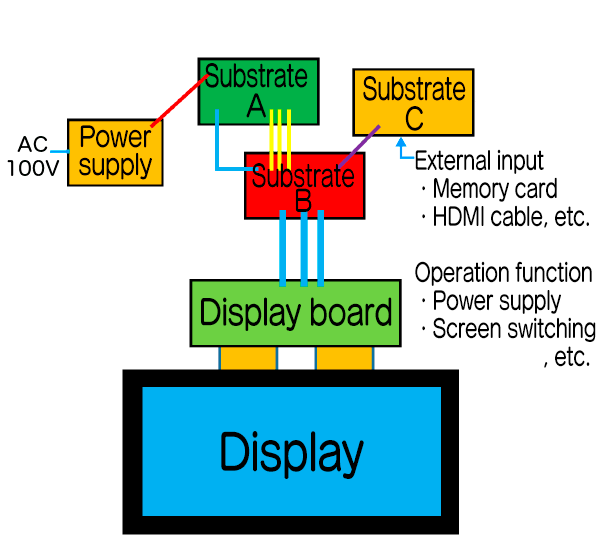

* In order to drive a display with a commercially available drive board, a large number of boards and harnesses connecting them are often required as shown in the example shown in the figure. Since few commercial products have all the functions to control the display, they are often used in combination with a custom-made board to achieve this condition.

Example

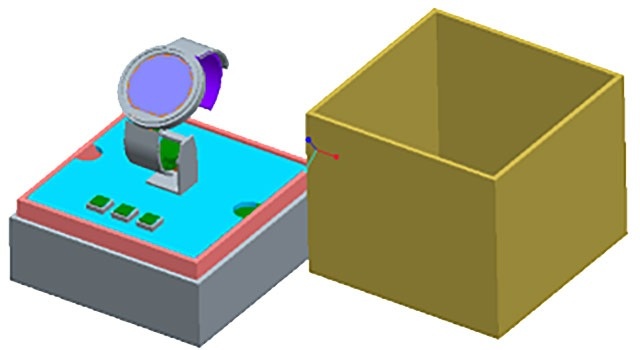

Clock type demo machine

- Drive board, display: Customer-supplied

- Clock part shape design: Request to a design company

- Structural design / 3D data creation → Modeling / painting: Our company

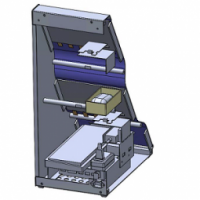

E-POP

- Drive board, equipment, display: Customer-supplied

- Shape design: Our company

- Structural design / 3D data creation → Modeling / painting: Our company

Direct bonding exhibition

- Drive board, equipment, display: Our selection and procurement

- Shape design: Customer (rough idea), partner company

- Structural design, manufacturing: partner companies

- Assembly: Our company

- Software: Our company (basic part), customer (content)

In addition, we also undertake the following operations

- External design / parts procurement / bonding of FPC / PCB

- Design and procurement of display module parts (gold frame, frame, cover glass, tapes, etc ...)

- Design-procurement of jigs and tools used in our prototype process

- Design-procurement of jigs and tools used in the customer process and in the customer evaluation environment

If you can consult us other than the above, we will consider it.