Laminating and assembling the liquid crystal panel

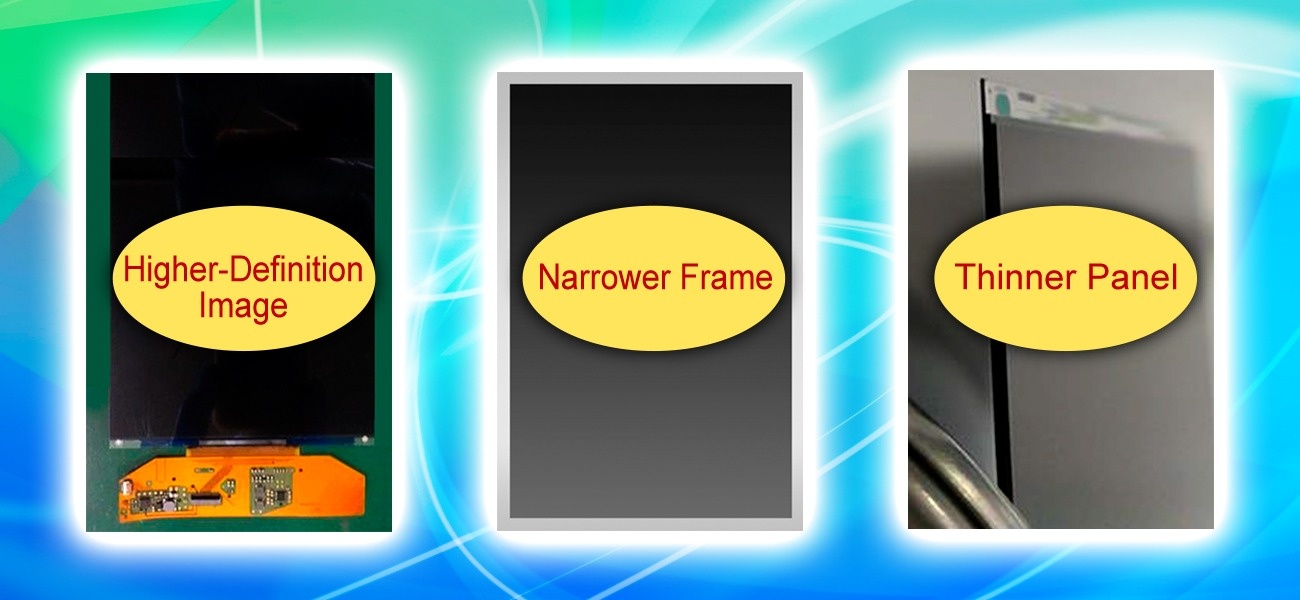

In the field of Flat Panel Displays (FPD), enhancement of image definition, reduction of panel thickness and narrowing of frame width are being accelerated today. We are always watching the market trend and proactively introduce new technology in mounting and assembly in order to meet our customers' needs and requirements.

Features of our flat panel display mounting business

- Abundant prototype results (mass production is also supported) more than 100 prototypes per year

- Short delivery time due to domestic support

- Abundant equipment, laminating accuracy

- Consistent support for module process

- Cooperation with in-house laminating technology (bare chip laminating, LED laminating, etc.)

Owned technology

Display module laminating technology

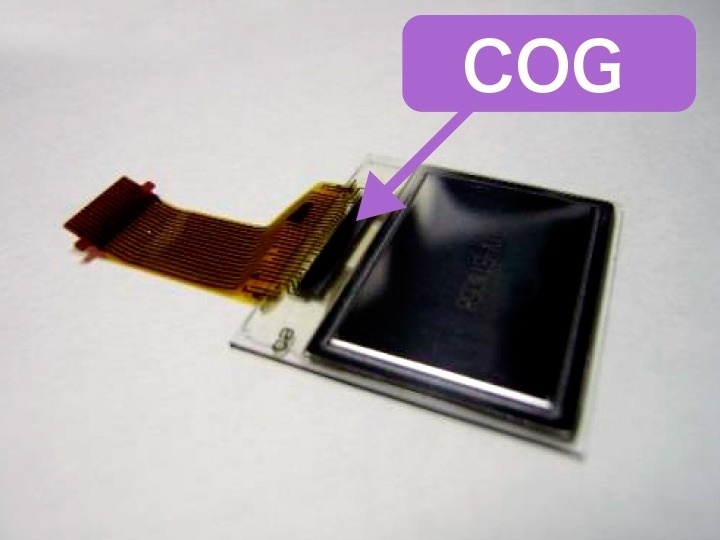

- Driver laminating (COG / COF)

- FPC laminating by ACF connection

Display panel laminating / assembly technology

- Polarizing plate and touch panel laminating

- Direct laminating

- Optical boning (OCA / OCR)

- Back-light unit assembly

- Atmospheric and vacuum laminating

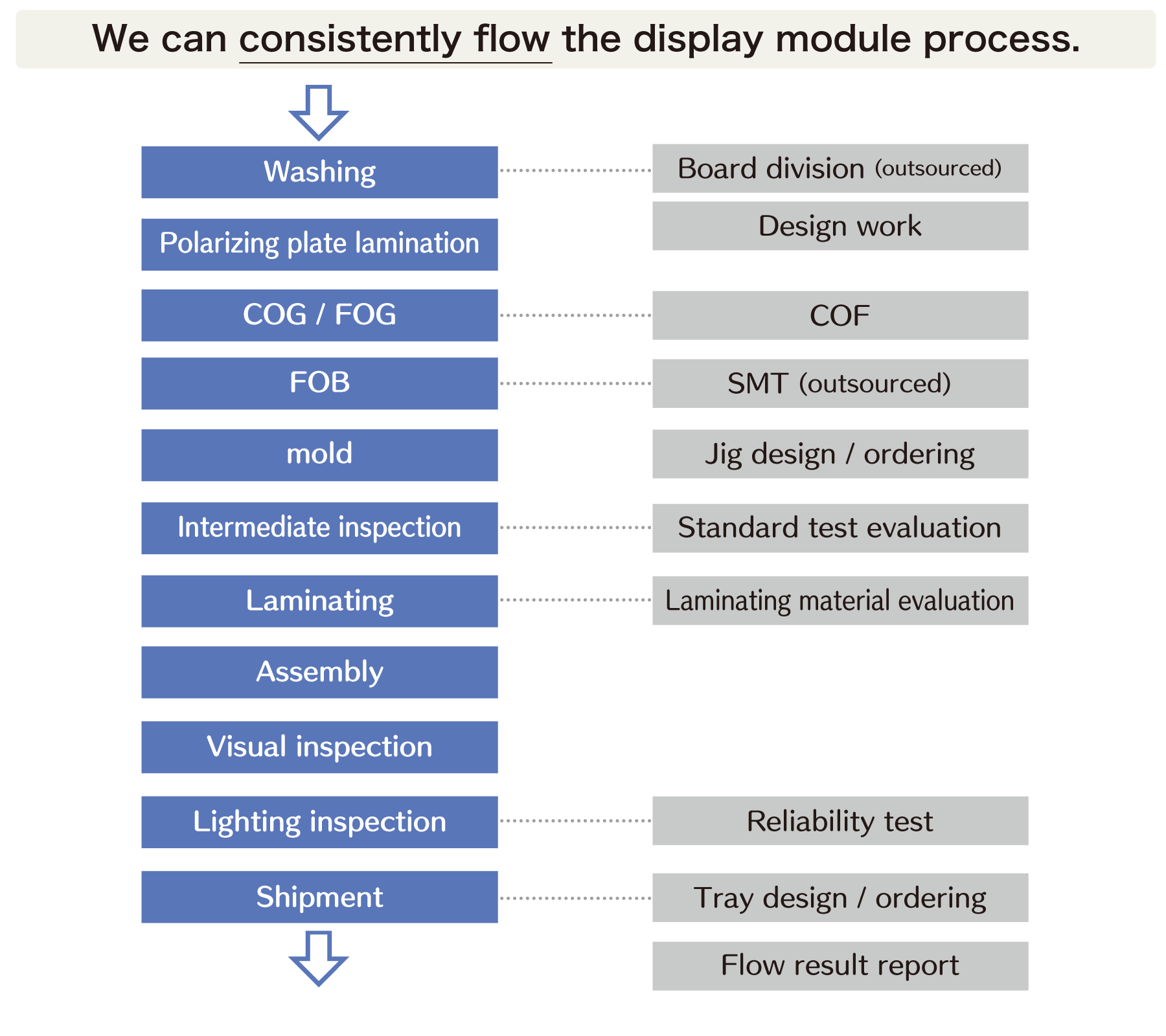

Display module process consistent support

Equipment

COG bonding machine for FPD

Basic specifications

- Compatible with 1 to 17 inch size panels

- Supports 2-sided bonding (up to 6 ICs)

- Automatic bonding from ACF bonding, temporary bonding to main bonding

- Compatible with a large number of ICs and small-lot production

COG bonding machine

Basic specifications

- Corresponding panel dimensions: 5 inches

- Dr length: 55mm

- Bonding accuracy: ± 4.5 micron

About Display-related equipment

Laminating example

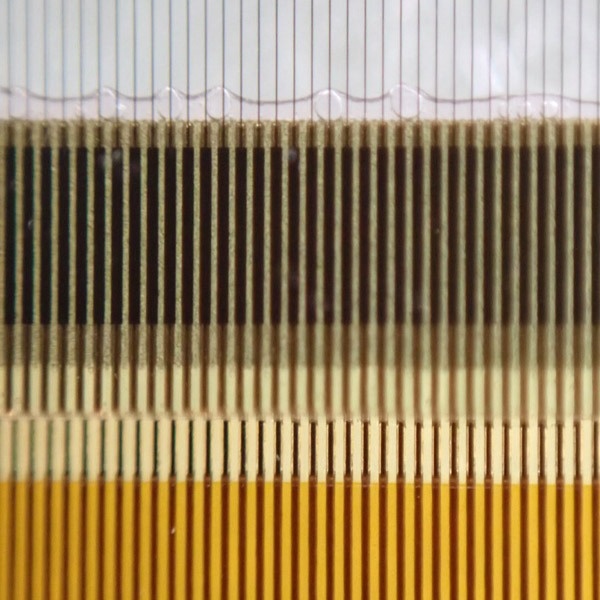

Miniaturization associated with higher-density COG

Performance of ACF bonding at the time around the year of 2000

Chip Size:~22mm *Pitch:90μm(COG)

↓

Performance of ACF bonding now

Chip Size:~35mm *Pitch:36μm(COG)

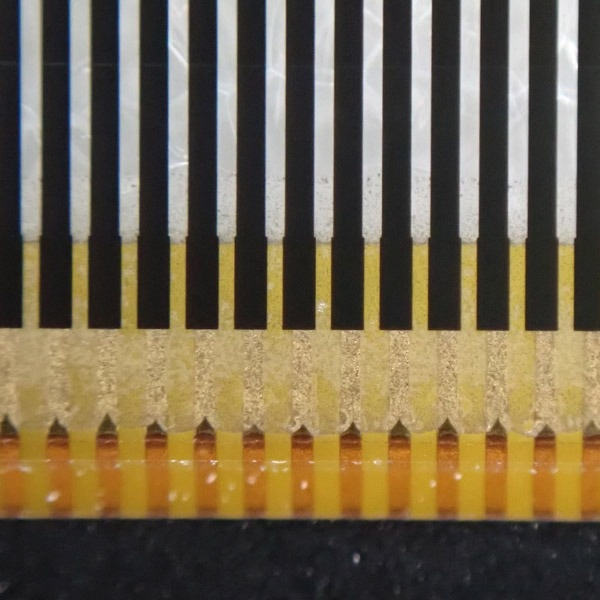

Miniaturization with FOG high definition

ACF laminating results around 2000

Connection length ~ 40mm / pitch: 200μm

↓

Current ACF laminating results

Connection length ~ 150mm / ◎ Pitch 70μm (center)

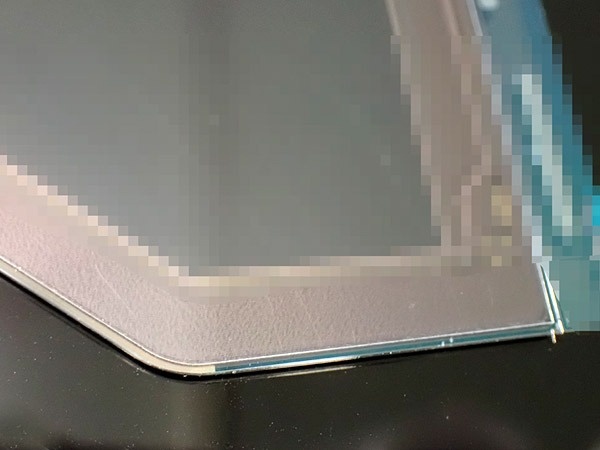

Compatible with thin and irregularly shaped glass

Shape of LCD glass around 2000

0.4mm glass on one side, rectangular shape

↓

Current LCD glass

0.15 mm glass on one side or non-rectangular irregular shaped glass

Laminating a polarizing plate to irregularly shaped glass

Laminating a polarizing plate to irregularly shaped glass

Achievements of FPDs other than LCD

We have been laminating and assembling various FPDs other than LCD (Liquid Crystal Display).

- Glass substrate OLED (active, passive)

- Film substrate OLED (active, passive)

- Electronic paper

- Film liquid crystal

- Capacitive touch panel

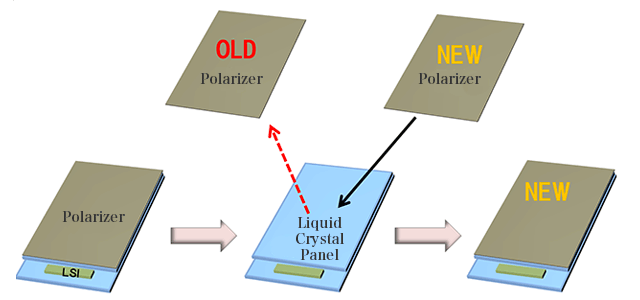

Repair of Polarizer (Remove an old polarizer→bond a new polarizer)

- work size: ~15inch

- panel thickness (Min):0.3mm~(CF: 0.15mm, TFT: 0.15mm)

- LCD:can be recycled POL:cannot be recycled

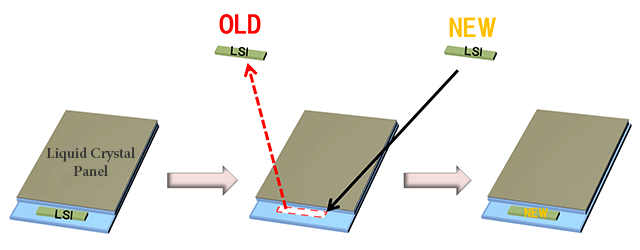

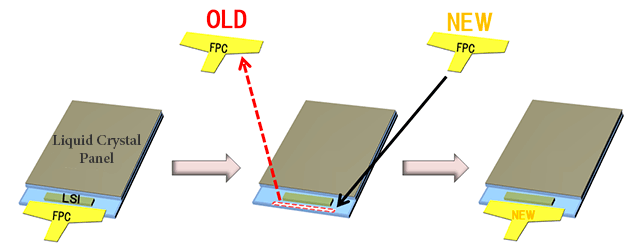

Repair of COG (Remove an old DrIC→Bond a new DrIC)

- DrIC length (Max): ~32mm

- panel thickness (Min): 0.3mm~ (CF:0.15mm, TFT:0.15mm)

- LCD:can be recycled DrIC:cannot be recycled

Repair of FPC Bonding and Removal of ACF (Remove an old FPC→Bond a new FPC)

- panel thickness (Min):0.3mm~ (CF:0.15mm, TFT:0.15mm)

- In some parts, removed FPC can be reused and bonded.

- LCD:can be recycled some FPC:can be recycled

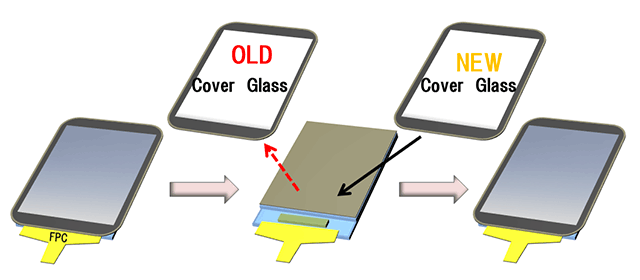

Repair of Bonding junction (Remove an old CG→bond a new CG)

- work size (Max):~7inch *For work of 12 inch or more, consult with us.

- panel thickness (Min):0.3mm~ (CF:0.15mm, TFT: 0.15mm)

- LCD:can be recycled CG:can be recycled POL:cannot be recycled

About various laminating technologies

We also undertake various tests and evaluations.

Reliability test

Heat shock, high temperature and high humidity, high temperature reliability test is possible. We carry out environmental tests according to customer requirements.

Reliability test equipment