Prototype development evaluation of production goods

Prototype evaluation and manufacturing processes build support of production goods and development of laminating

Do you have such a request?

- I want to build an optimal laminating process to market my product

- I don't want to fail because it is one of the few prototype parts

- I want effective data for selling in-house developed production goods (films and adhesives)

- I want to be present, so I want you to respond at the domestic factory

- I want to make a prototype with a short delivery time

- I want to make a demo set for the exhibition

- I will give you prototype materials (levels, etc.) so I want to leave it to you

"Laminating technology" cultivated through the number of prototypes and abundant experience

More than 100 prototypes of FPD (flat panel display) are produced annually. We support development and prototyping with the "laminating technology" cultivated through many prototypes.

・ High-precision laminating

・ Technology and process know-how

・ Supports a wide variety of panels

・ Supports a wide range of processes

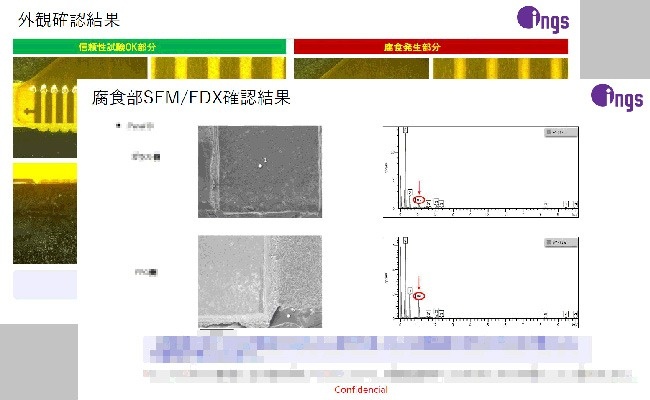

Feedback on technical issues, analysis, process improvement proposals

We solve technical problems such as laminating accuracy, prototype analysis, and optimal process construction know-how.

・ Prototype that you do not want to fail

・ Trial prototype

・ Feedback of evaluation verification

・ Feedback on technical issues and solutions to issues

You can leave it to us from the implementation of high-difficulty prototypes to the provision of various information.

Please leave the entire progress management of the prototype.

Please leave the whole prototype level.

We will organize and prototype the troublesome standard materials just by presenting it, which will reduce the management man-hours of the customer and allow to concentrate on the original work such as evaluation and verification of the prototype results.

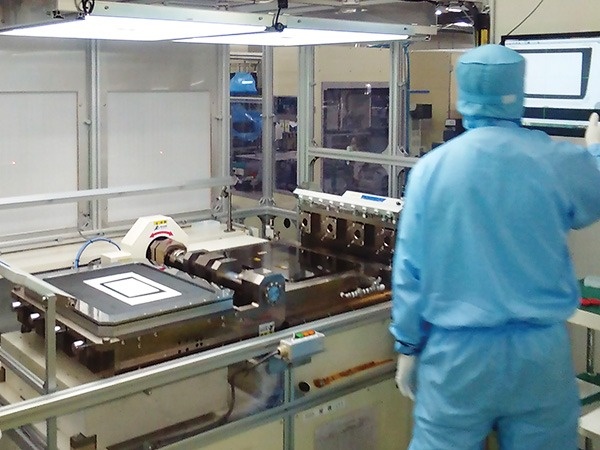

Correspondence at domestic prototype factory in Japan

Our laminating factory will be supported at the domestic factory (Shimosuwa Town, Nagano Prefecture, Japan).

・ Witnessing prototype manufacturing

・ Shorter lead time compared to overseas

・ It is possible to respond with a small turn, such as quick delivery.

There are merits such as. Please use our company.

Examples of prototype production goods that we have been involved in so far

OCR development product evaluation

- Material: OCR for direct bonding

- Combination: glass + glass, etc.

- Delivery time (approximate): About one week

For the evaluation of the characteristics of the newly developed OCR, it is laminated at our machines. It was used for workability and understanding of characteristics in an actual usage environment different from that of the manufacturer's laboratory.

Exhibition demo set production

- Material: Anti-reflective film

- Combination: glass + film, etc.

- Delivery time (approximate): About 2 to 3 months

A film maker ordered a cover glass and a development film on the lit LCD module for exhibition at the exhibition.

They used it as it is at the exhibition.

Film characterization

- Material: Functional film

- Combination: Glass + film

- Delivery time (approximate): 2-3 weeks

A film maker made a prototype to replace the film of an existing product by comparing it with other companies' products.

Using the repair technology cultivated in polarizing plate repair, we peeled off the films of other companies' existing products and laminated the developed products together.

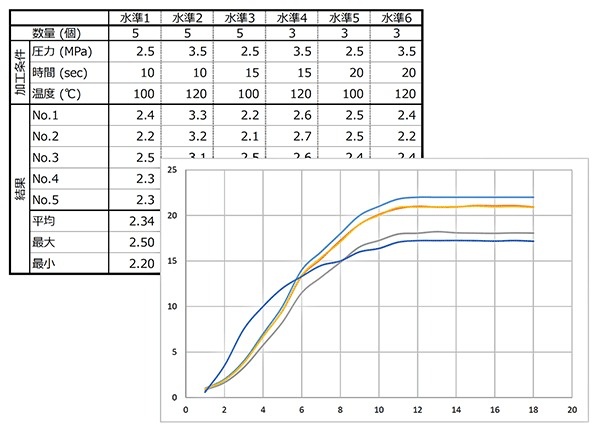

Film basic evaluation processing / laminating

- Material: Functional film

- Combination: Film cutting, laminating, etc.

- Delivery time (approximate): 1 to 2 weeks

For the basic evaluation of the newly developed functional film, outer shape processing, protective film and OCA are laminated.

Prototype for mass production periodic monitoring

- Material: Organic material

- Combination: Implementation, etc.

- Delivery time (approximate): 1 to 4 weeks

For regular monitoring of production goods during mass production, we have semi-finished products supplied to us and process them to the point where electro-optic evaluation is possible.

Film LCD process verification

- Material: LCD dimming device

- Combination: LCD sheet + protective material, etc.

- Delivery time (approximate): 1 to 4 weeks

For a dimming device using a film material under development, we made a prototype of laminating a protective material. We confirmed the workability of the laminating materials (OCA and OCR) and provided feedback.

Film liquid crystal characteristic verification

- Material: LCD dimming device

- Combination: LCD sheet + protective material, etc.

- Delivery time (approximate): 1 to 4 weeks

For a dimming device using a film material under development, we examined the outer shape processing method with a partner company, processed it, bonded it on FPC, and laminated a protective film.