LED bonding for evaluation Part 2

Continuing from the previous session.

We bonded the LED.

First, we decided to use anisotropic solder as the bonding material. Anisotropic solder is a material in which solder particles are dispersed in a thermosetting resin. By heat treatment, the solder particles aggregate and melt to form an electrical connection, and at the same time the resin is cured. It is a material that is also mechanically fixed.

First, apply a paste-like anisotropic solder material.

here are two small lands on the right side of the silk-printed letter "S", and the paste is applied to them. Using a dispenser, apply the same amount of solder paste to the anode and cathode as much as possible.

Place the LED on this. Since the LED is small, we use a mounter.

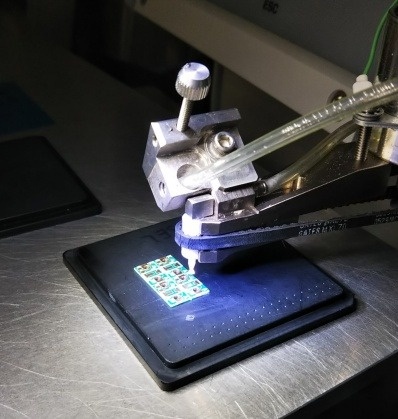

This is a manual operation mounter.

Finely adjust x, y, and θ while checking with a microscope, and mount the chip.

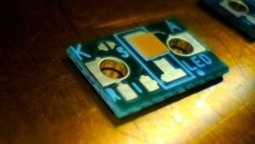

The photo below shows what it looks like after it is placed.

Since the LED electrodes are formed under the chip, you cannot see how they are connected.

The board this time is a general-purpose board. Therefore, the mounting position is also a measure.

We checked the LED specifications in advance and measured the gap between the electrodes on the board, so it seemed unlikely that there would be a short circuit, but there is a possibility that a short circuit will occur with cream solder or silver paste. Was not zero, so we used anisotropic solder.

Even if anisotropic solder is applied across narrow electrodes, the risk of short circuit is less than that of isotropic conductive materials (conductive paste, solder, etc.) because the solder particles aggregate during curing.

All that remains is heat treatment.

Hold in the oven for the specified time and temperature conditions to complete.

Lights up safely!

We thought that the 1.1mm square might have a bonding defect, but we were able to confirm that all of them were lit.

How was that.

This time, we introduced the bonding scenery for individual evaluation using a large LED among the mini LEDs. As LEDs become smaller and become about 0.2 mm square, the selection of connection materials becomes more careful, but as a result, 0.2 x 0.1 mm LEDs can also be bonded with a high yield.

In this way, we also undertake a small amount of bonding for evaluation, so please do not hesitate to contact us from the Web inquiry form.

(End)