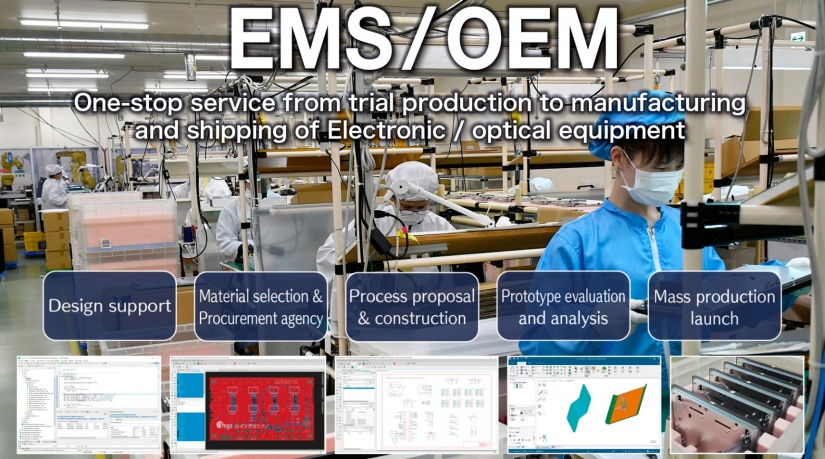

EMS/OEM Contract manufacturing service

Ings Shinano undertakes EMS (Electronic Manufacturing Services) and OEM production, which undertakes everything from design and trial production of electronic devices to mass production and shipping.

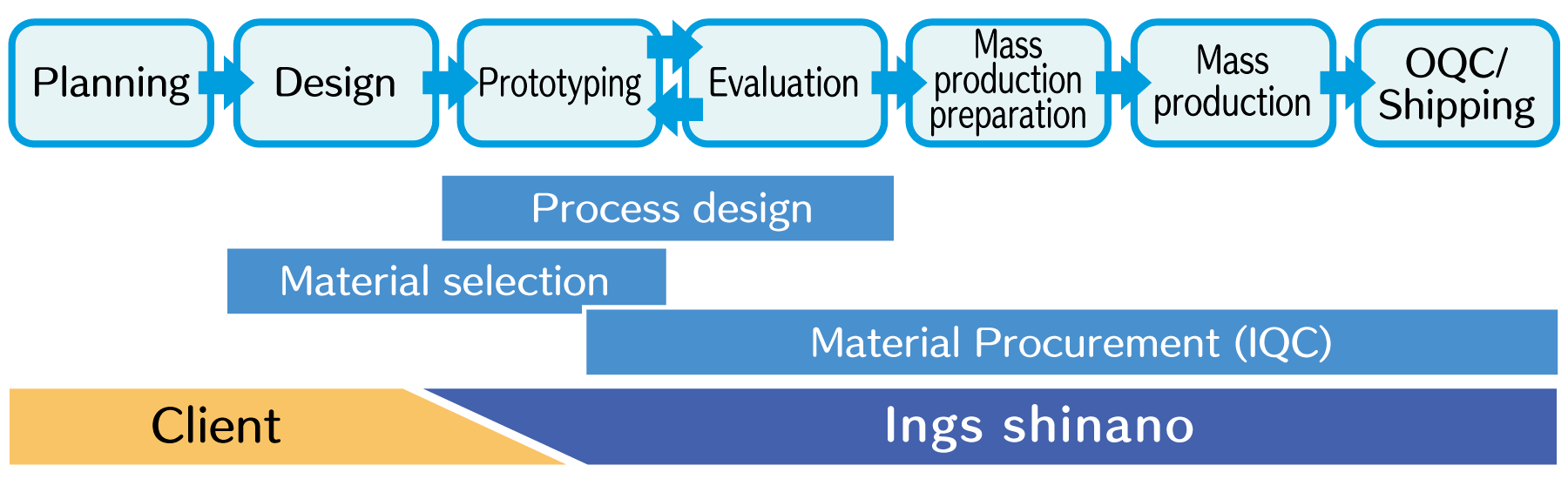

Flow of introduction of EMS / OEM contract manufacturing and scope of business support

Features of Ings Shinano EMS / OEM contract manufacturing

Providing one-stop service

Procurement, selection of suppliers, cost reduction, partner companies

Assembly work in a clean room

We have a 3300m2 (9 floors) clean room (managed by 0.5μ particles 300-3000 or less) and achieves high quality in a clean environment.

Human resources who have received advanced skills and technical education (national certification) for assembling electronic components

We can also handle assembly work that requires advanced skills such as electronic equipment assembly and optical equipment assembly (some human resources have acquired the first grade of optical equipment assembly, which is a national certification).

Supporting manufacturing with bonding technology cultivated through various prototypes

We are making a large number of various prototypes such as bare chip bonding and display module bonding. Our technology is useful in the manufacture of electronic devices with various mountings.

Product concept realization ability unique to abundant prototype experience

We have the ability to realize commercialization from various aspects of cost, quality, and technology.

This is because we can undertake development contracts to realize our customers' "product planning concepts" with the comprehensive strength of bonding, display modules, optical equipment, and precision equipment assembly such as electronic devices.

Product case

Composite IoT sensor

A small IoT product that requires multiple sensing functions and wireless communication functions.

Scope of contract: Housing design / manufacturing, assembly, inspection

Assembly of other products

Mechanical equipment assembly, Optical equipment assembly, Electrical / electronic equipment assembly, Information related equipment assembly, Measurement equipment assembly, Office equipment assembly, Crystal oscillator assembly & inspection, Integrated assembly from built-in board mounting

Quality control / product evaluation

Obtained ISO9001 and IATF16949

We implement customer inspection and quality standards to the field level and appropriately perform quality control.

In December 1999, we acquired the quality management system ISO9001 certification. December 2016 we also acquired ISO9001: 2015 version of certification registration certificate, and the transition of 2015 version has been completed.

In addition, on February 21, 2019, the in-vehicle quality management system acquired IATF 16949 standard certification from the inspection body (BVCC).

Product evaluation

We strongly support our customers' quality activities such as quality and reliability evaluation of various information devices, electronic parts, electrical parts, boards, and units.

Click here for inquiry and quotation request.