Bare chip bonding Proposal for solving technical problems of COB

Solving various problems with bonding technology

Bare chip bonding

Respond to any small request for bonding:1 string of wire, 1 piece of panel, etc.

Quick delivery.

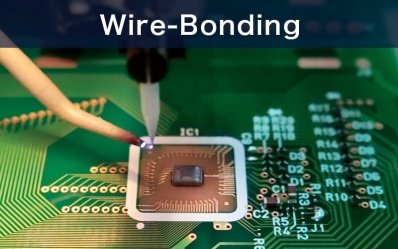

gold wire, aluminum wire, gold wire ribbon, etc.

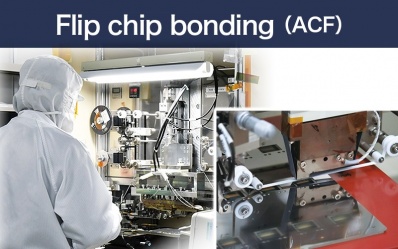

Mounting forms include interconnection between glass substrate (panel) and FPC, COG (Chip On Glass) bonding, COF (Chip On Film) bonding, substitution for connector or solder, etc.

We perform airtight sealing centered on seam welding technology for sealing LEDs and MEMS.

It supports not only vacuum but also filling of inert gas and leak test.

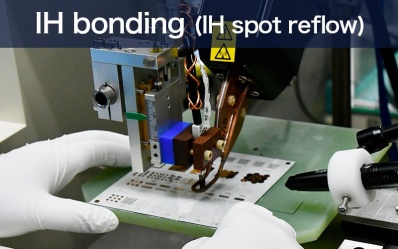

IH spot reflow is a technology that uses induction heating (IH) to locally heat only the metal part and perform soldering.

Since it is heated by induction heating, only metals such as solder and leads generate heat.

We can handle business processes related to bonding collectively.

In addition to the technical aspects, we provide full support for operations related to prototype evaluation by providing small-scale support such as procurement and single-shot trial production.

- Prototype evaluation support from 1 piece

- We also support prototypes only

- Parts selection, material procurement

- Prototype with trial. Please contact us even if the bonding is refused by another company.

Main machines

| Rotary head (automatic) Aluminum thin wire bonder | Wire diameter: 25-75 μm

Minimum pad pitch: 100 μm

Bonding area: 300 x 160 mm |

|---|---|

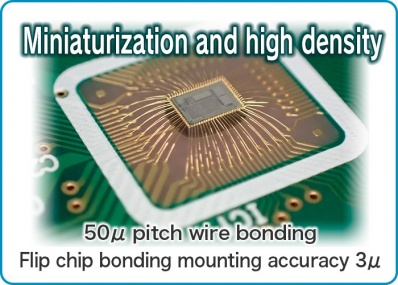

| Gold wire Wire bonder Wire diameter: | Wire diameter: 18-50 μm Minimum pad pitch: 50 μm Board size: 80 x 250 mm |

| Mini LED die bonder | Board size: □ 300 mm

Chip size: □ 0.1mm ~ □ 1.1mm

On-board bonding accuracy: ± 25 μm (3σ) (both x and y) |

| High-precision flip-chip bonder | Bonding position accuracy: 3 μm (3σ)

High-precision bonding of 0.3 mm square LED bare chips is possible

Pressurized range: 5N to 490N

Heating range: Max.500 ℃ |

| IH spot reflow | Single head basic evaluation equipment |

Abundant problem-solving achievements and experience points. Introduction of proposal cases

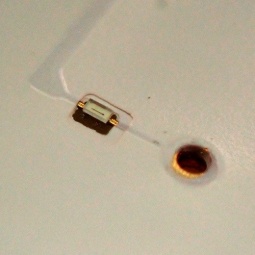

Equipped with LED for evaluation of developed products of paste material for wiring

- Theme: If you need to connect an LED for material evaluation. How should we connect?

- Proposal: Proposal of circuit configuration and component constants, creation of wiring patterns. Proposal of bonding method.

- Solution: Bonding the LED with a silver paste connection.

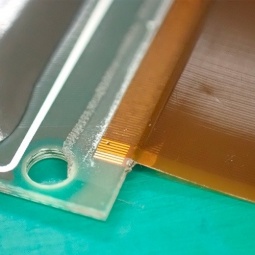

Connection of film material with low heat resistance and FPC

- Theme: IF you need to connect FPC to a film with electrodes formed on PET film. Highly reliable and low profile is desired.

- Proposal: Propose FOF implementation using ACF. We also provide advice on the selection of ACF materials.

- Solution: FOF enables connection, low profile (bonding height is almost zero), and highly reliable connection.

Click here for inquiry and quotation request.