The feature of the Packaging Business

One-stop service for board bonding prototype and mass production

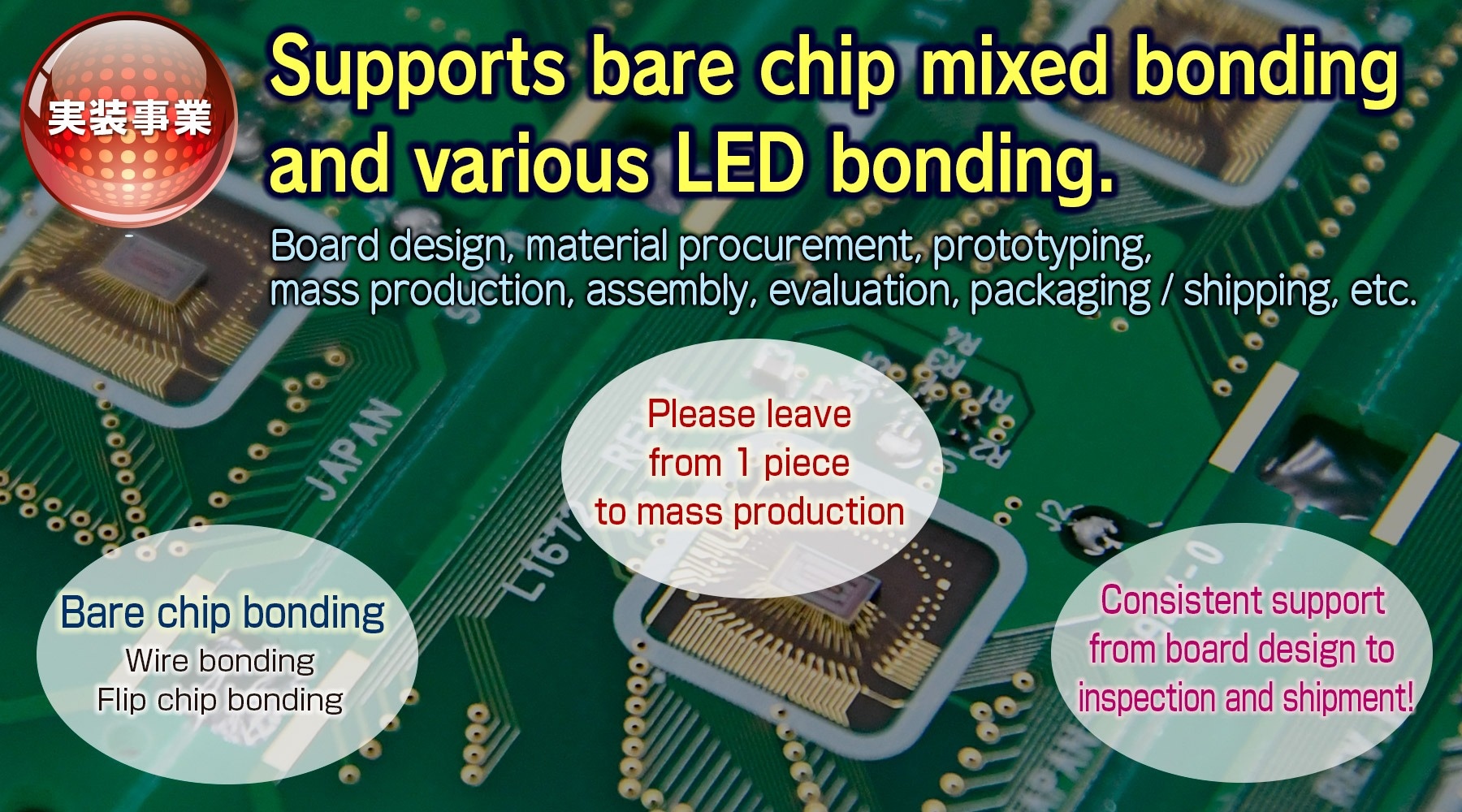

For wire bonding, bare chip bonding such as ACF and FCB, and SMT, we consistently handle board design, material procurement, bonding, assembly, quality evaluation / guarantee, packaging / shipping, etc.

- We support trial production to mass production.

- We accept IC chip dicing, tray transfer, and backgrinding. We also accept modularization.

- We accept rework / repair from one wire.

Features of Ings Shinano bonding Business

- Feature 1: Supports a wide range of bonding technologies

- Feature 2: Supports from 1 prototype to mass production: Abundant prototype experience & bare chip bonding experience and knowledge

- Feature 3: Quick delivery

- Feature 4: Consistent support from board design to inspection and shipment

- Feature 5 Please leave the process design and manufacturing process construction to us.

Feature 1 : Supports a wide range of bonding technologies

COB (chip on board) bonding image

COF (chip on film) bonding image

Introduction of various bonding processes

Can be bonded to various substrates

Feature 2 : Supports from 1 prototype to mass production

We accept mass production (from 10 pieces) from 1 prototype to a small amount.

In the prototype, we back up the proposal and construction of the manufacturing process from the meeting of specifications. We can handle everything from selection to procurement of the materials required in the manufacturing process.

In the trial production, we will also provide feedback on the prototype results.

We provide proper prototype manufacturing from our abundant prototype experience for the construction of the customer's bonding process.

Contract flow for bonding prototype and mass production

- Inquiries / Inquiries

- Specifications meeting (A meeting is also possible by visiting)

- Preliminary bonding experiment (when the difficulty level is high and it is necessary to confirm whether or not bonding is possible in advance)

- Arrangement of prototype parts (We can also arrange boards, parts, and materials)

- Receipt of supplied materials (supply of key parts)

- Prototype (If you need a report, we will create it as well)

- Prototype delivery / prototype result report

When proceeding to mass production ...

- Proceed with prototype steps (development prototype, technology prototype, mass production prototype)

- Meeting for mass production study (Mass production schedule adjustment)

- Preparation for mass production (line design, QC process chart establishment, jig, production equipment arrangement)

- Mass production line audit (audit by customer's product certification department and purchasing department)

- Mass production prototype

- Mass production review (We will do it ourselves, but we will report it as needed)

- Mass production start

Feature 3 : Quick delivery

We perform prototypes and mass production with quick delivery with a small turn. Please contact us for urgent matters.

We would appreciate it if you could inform us of the following requirements when making a request with a short delivery time.

◎ Desired delivery date

◎ Quantity

◎ On-board device

◎ Device supply form

◎ Specification of bonding method

◎ Mechanical drawing

◎ Circuit diagram

◎ List of supplied materials and materials procured by us

◎ Packing method

Feature 4 : Consistent support from board design to inspection and shipment

We will make the best use of the strengths of each regional collaborative company network and respond to all his requests from our customers in a one-stop and prompt manner.

Feature 5 : Please leave the bonding "process construction proposal".

We will propose an appropriate bonding method after asking the customer's request regarding bonding, device specifications (temperature, usage conditions, etc.) and application.

Even for customers who do not know the bonding method, we will make a proposal after asking about the conditions such as the intended use. We will scrutinize whether the fixed bonding method is difficult to realize, and even if it is difficult, we will propose another plan.

Past achievements (industry field)

- LED Printer Printer Head: LED Wire Bonding

- Sensor element evaluation board: element wire bonding, board design, biosensor

- RFID tag: Wire bonding of RFID IC

- Image sensor: Wire bonding of CMOS sensor

- Power IC (FET, IGBT): Aluminum thick wire wire bonding

- LED: Indicator lamp, special purpose irradiator

- COB of the main microcomputer of the stopwatch

- Mini LED: Prototype for various evaluations

- Pulse wave sensor LED and PD bonding

- COF: ACF bonding of driver IC

Click here for inquiry and quotation request.