2.5D lamination

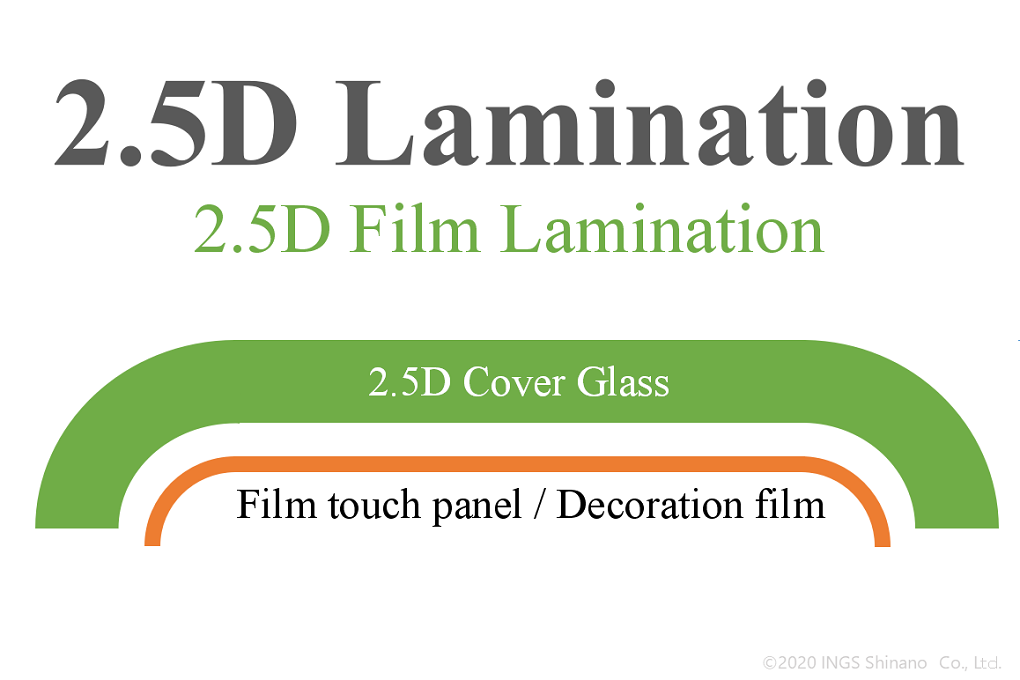

When using the 2.5D cover, the film material may be laminated.

Compared to ordinary flat plate cover glass, 2.5D glass is more difficult to print with a frame or design, and a decorative film may be laminated.

In addition, film touch panels and film-based displays also need to be laminated directly to the inside of the glass in order to ensure characteristics and improve visibility.

Design films and touch panels are often laminated to concave surfaces, but functional films such as shatterproof and antireflection are often laminated to the convex side.

In either case, it is difficult to apply without air bubbles or wrinkles along the bent cover, and it is necessary to search for the conditions while trying the actual product.

The photo below is an example of actually pasting a film on curved glass.

A polarizing plate is attached for easy understanding.

An example of this is laminating a film on glass with a large R, but we also have a prototype of laminating on a small R, such as inside a smartphone cover glass with curved sides.

In addition to laminating the film touch panel on the display side, we hope that it can be used for applications such as pasting decorative films as a printing alternative to the back glass.