About OCA

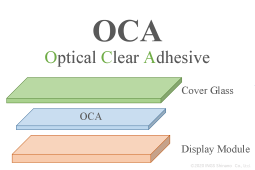

OCA is an abbreviation for Optical Clear Adhesive.

If there is an air layer between the display and the cover glass / touch panel, etc., the appearance will deteriorate due to interfacial reflection. To improve its appearance (to reduce interfacial reflection), the space is filled with a material with a refractive index close to that of the material to be bonded. OCA is one of the materials that fills the space.

For details, see "About direct bonding".

Features of OCA

The advantages over OCR are that it is easier to handle than OCR, where the resin sticks out, the thickness is uniform in the plane, and there is little variation between individuals.

On the other hand, compared to OCR, it requires more thickness to absorb the printing steps on the cover glass. Also, it seems that the cost competitiveness is a little inferior because it is necessary to make the adhesive material into a sheet and cut it into the required shape.

OCA has a large number of products from various manufacturers, mainly acrylic and silicon. In addition, there is also a type that can obtain higher adhesive strength by irradiating UV or applying heat after laminating to promote the reaction, and select it according to the application.

About the process

In the OCA method, a tape-processed adhesive is attached to one panel and the other panel is laminated. Depending on the material, rollers may be laminated under atmospheric pressure, or workpieces may be laminated in vacuum. We have various laminating devices. In addition to laminating flat surfaces, we are also working on laminating curved surfaces.