Flip chip bonding

What is a flip chip?

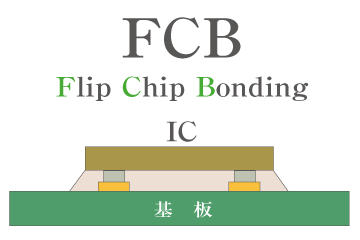

Flip-chip bonding is a method of bonding a bare chip (a semiconductor cut out into a chip) by inverting (flip) it.

Before the advent of flip-chip bonding, wire bonding was the mainstream for semiconductor bonding. Since wire bonding connects the chip and the substrate with a wire, the active surface of the chip was the upper surface. On the other hand, in flip-chip bonding, the active surface faces downward and is mounted facing the board surface. It is called a flip chip because the chip faces the opposite side of the wire bonding.

Flip chip bonding features

Comparing flip-chip bonding and wire bonding has the following advantages.

- Space saving compared to wire bonding

- Wiring length is shorter than wire bonding, and there is less inductance component (suitable for high frequencies)

- Since it is directly connected, the resistance value is low and the loss is low.

- Since the terminals are connected at once, the throughput is high in the case of multiple terminals.

Application of flip chip mounting

Flipchip bonding can be applied to various locations such as bonding on an IC package, bonding on a PCB board, and connecting a multi-chip IC to an interposer.

Flip chip bonding process

In flip chip bonding, a semiconductor chip is bonded with high accuracy using a dedicated bonding machine (flip chip bonder).

In addition to ACF connection, electrical connection is made by ultrasonic connection.

Ings Shinano supports flip-chip bonding with ACF connection.

We accept small-scale prototype service for flip chip bonding!

We accept advanced flip chip bonding, prototyping, joint reliability evaluation, etc.

We can handle from one flip chip to trial production to mass production in a short delivery time. Please feel free to contact us for more information.

We are capable of high precision die bonding and ACF boning! We can handle from one flip chip to trial production to mass production in a short delivery time. Please contact us for more information.