About 2.5D cover

In recent years, the number of touch-enabled displays used in smartphones, home appliances, and in-vehicle devices has increased, and curved covers have appeared as part of improving design.

At Ings Shinano, we laminate to bent covers.

Lamination to curved surface

Of the bent covers, the shape that is made by bending one plate is called the 2.5D shape. Since the shape of glass can be processed by thermal bending, we often see smartphones with 2.5D cover glass.

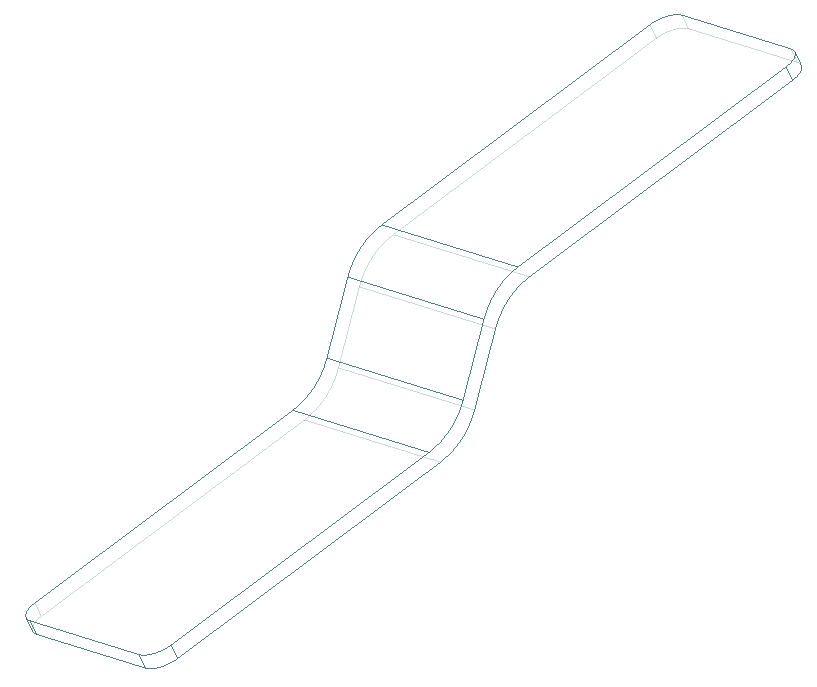

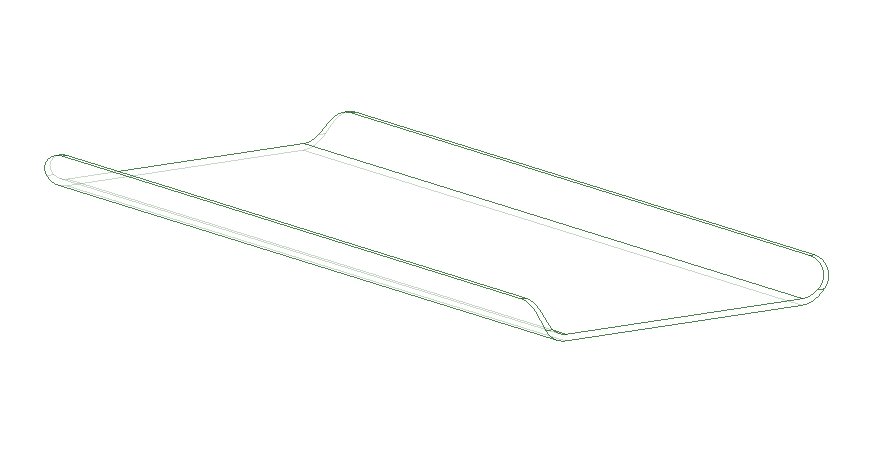

The figure is an example of a 2.5D cover.

"Part 1" is a large size with a long side of about 1,000 mm, and it bends greatly in the middle.

"Part 2" is a form often seen on smartphones. Left and right are curved.

Part 1

Part 2

These 2.5D cover glasses have a higher design than ordinary flat cover glasses (2D cover glasses), but it is difficult to laminate touch panels, displays, decorative films, surface protection films, etc.

Please refer to "2.5D Lamination" for laminating glass LCDs, etc. and "2.5D Lamination" for laminating decorative films and film touch panels.

2.5D has various shapes, curved parts R, height as a materials, etc. Since it is not possible to easily judge "this shape can be laminated" or "this size is difficult", the engineers will consider the optimal laminating material / laminating method for each consultation. increase.

After all, extreme shapes (R is tight, size is large, etc.) are difficult, and we may give up at the time of examination, but the laminating machines and methods are evolving day by day. We will continue to challenge difficult shapes.