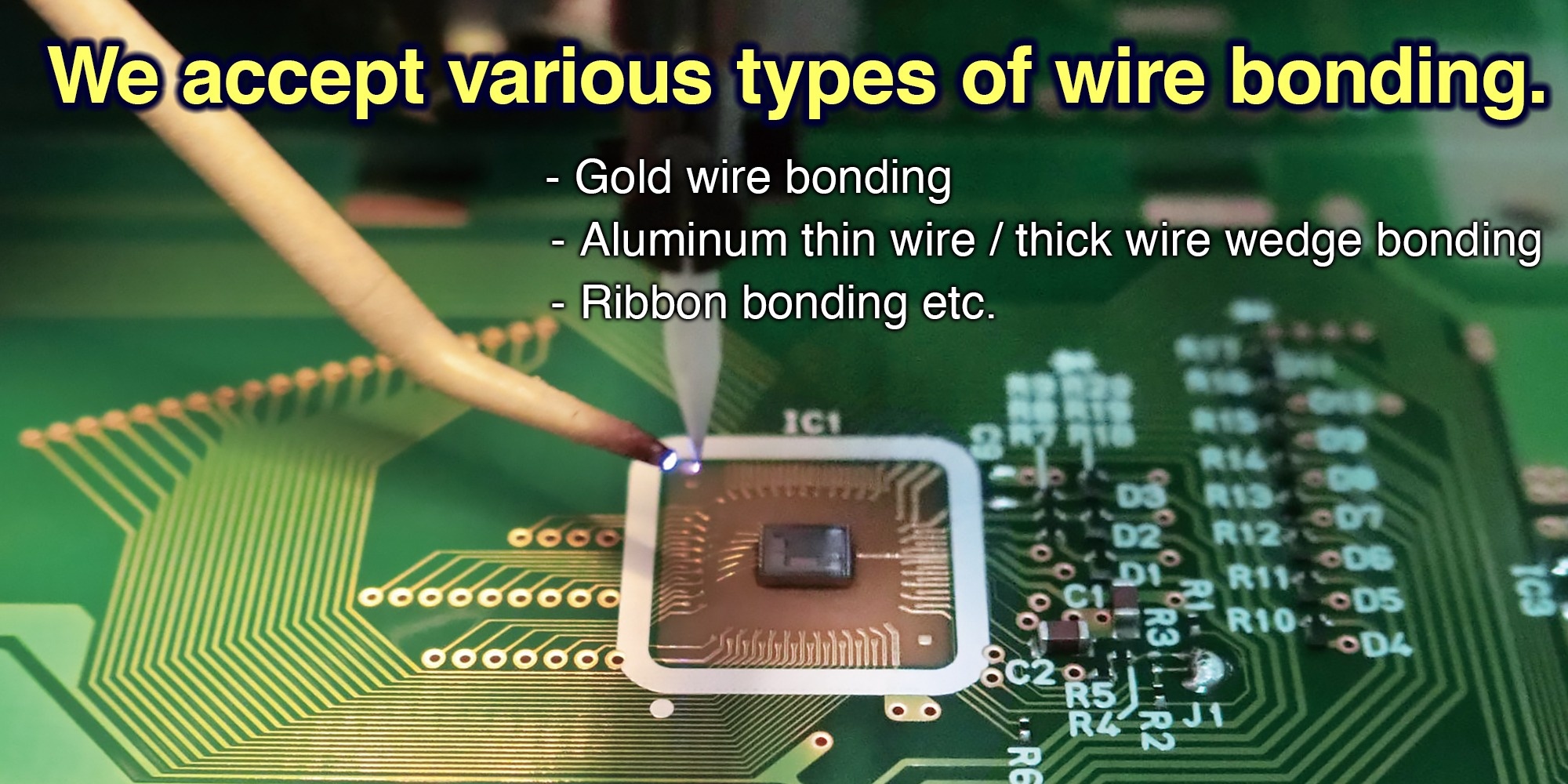

We can deal with ACF bondingi, thick aluminum wire bonding, and gold ribbon bonding which tend to be difficult for other bare chip mounting and prototyping companies.

- smartphone, digital camera, car navigation

- thermal printer, LED printer/li>

- digital/analog watch, wrist-worn pulsometer

- high frequency circuit board, X-ray inspection machine

- super hi-vision camera, RFID tag

- mountability evaluation, solutions for various problems with mounting, etc.

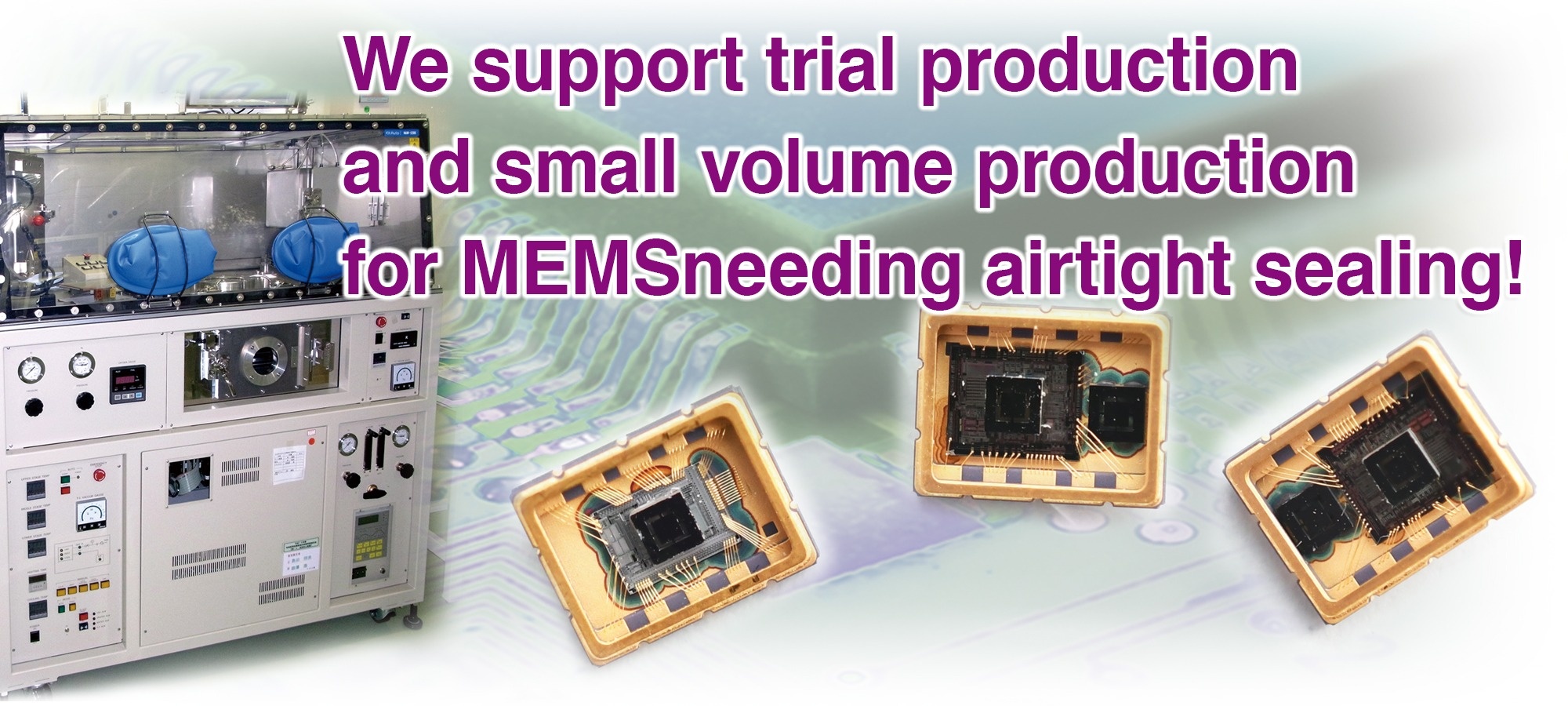

Product Category:MEMS sensors such as inertial sensors

Ordering Information (Unit/Form)

MEMS Package (Sealing/Seam welding)

- sensor of sealing with seam welding

- gas seal with N2 and other gases

- checking with leak testers

- quartz crystal oscillator, etc.

Bonding Material/Method

Product Category:Smartphone/Digital Camera/Car Navigation

Ordering Information (Unit/Form)

Middle to Small-Scale LCD Panel

- flip-chip bonding of Dr-IC on panel with ACF (COG)

- flip-chip bonding of Dr-IC on FPC with ACF (COG)

- interconnection between LCD panel and FPC with ACF (FOG)

- from design to prototyping of display unit

- OCA, OCR bonding

- mounting and assembly of touch panel

Bonding Material/Method

ACF (to ACF Mounting page)

Product Category:Thermal Printer/LED Printer

Ordering Information (Unit/Form)

Print Head

- mounting of Dr-IC on ceramic substrate with ACF

- interconnection between control board and FPC with ACF

- die-bonding/thin aluminum wire bonding of LED elements

- interconnection between PCB and ceramic substrate with gold wire bonding

Bonding Material/Method

- ACF (to ACF Interconnection page)

- thin Aluminum wire (to Wire Bonding page)

- Gold wire (to Wire Bonding page)

Product Category:Digital Watch/Analog Watch

Ordering Information (Unit/Form)

Display/Dial Face Light-Emitter

- die-bonding/thin aluminum wire bonding of LED on FPC

- die-bonding/gold ball bonding

- wire connection by gold ball bonding between PCB and glass substrate of digital display (EPD)

Bonding Material/Method

- thin Aluminum wire (to Wire Bonding page)

- gold wire (to Wire Bonding page)

Product Category:High Frequency Circuit Board

Ordering Information (Unit/Form)

Chip Mounting of High Frequency Circuit Board

- mounting by gold ribbon bonding

Bonding Material/Method

- gold ribbon (to Wire Bonding page)

Product Category:X-ray Inspection Machine

Ordering Information (Unit/Form)

Power Supply Circuit

- die bonding/thick Aluminum wedge bonding of IGBT to PCB

Ordering Information (Unit/Form)

Control Board

- interconnection between PCB and FPC with ACF

Bonding Material/Method

- thick Aluminum wire (to Wire Bonding page)

- Aluminum ribbon (to Wire Bonding page)

- ACF (to ACF Mounting page)

Product Category:Wrist watch type pulse monitor

Ordering Information (Unit/Form)

Sensing Portion

- high-precision die bonding/gold wire bonding of PD to FPC

- high-precision die bonding/gold wire bonding of LED to FPC

Bonding Material/Method

- gold wire (to Wire Bonding page)

Product Category:Super Hi-Vision Camera

Ordering Information (Unit/Form)

Image Sensor

- high-precision die-bonding/gold ball bonding of large-scale CMOS sensor to ceramic PKG

Bonding Material/Method

- gold wire (to Wire Bonding page)

Product Category:RFID Tag

Ordering Information (Unit/Form)

RF Element Mounting

- RF element mounting on paper substrate (Heat and Pressure FCB/gold WB)

Bonding Material/Method

- gold wire (to Wire Bonding page)

Product Category:Handy-Navi/Car Navigation/Mobile Phone

Ordering Information (Unit/Form)

Board for GPS

- C4 mounting of GPS functional IC

Bonding Material/Method

- Solder (to Flip-Chip Bonder page)

Product Category:Mountability Evaluation

Ordering Information (Unit/Form)

Resin Bonding Material Development/ Ceramic Bonding Material Development/Plating Evaluation/Engineering Plastic Bonding Material Evaluation

- evaluation of prototype of newly developed circuit board

- evaluation of products made in factories abroad

- mountability evaluation for development of various bonding materials

Bonding Material/Method

- X-ray inspection, bonding strength measurement, thermal shock test, heat cycle test (to Quality Evaluation/Tests page)

Product Category:Solutions for Various Problems with Mounting

Order Information (Unit/Form)

Repair of Developed Product/Wire Bonding Rework/Prototyping of New Product at Early-stage of Development Without Applying Mounting Rules

- We want to make good use of the few prototype IC's and substrates. Can we recycle and reuse those after test and evaluation?

- Some wire accidentally collapsed during evaluation.

- We have made a prototype and its profile exceeds the specs of our own machine, but we want to transfer it to mounting by all means.

Bonding Material/Method

- Ggold wedge bonding, gold ribbon bonding, thick aluminum wire bonding, aluminum ribbon bonding, thin aluminum wire bonding (to Wire-Bonding page)

Click here for inquiry and quotation request.